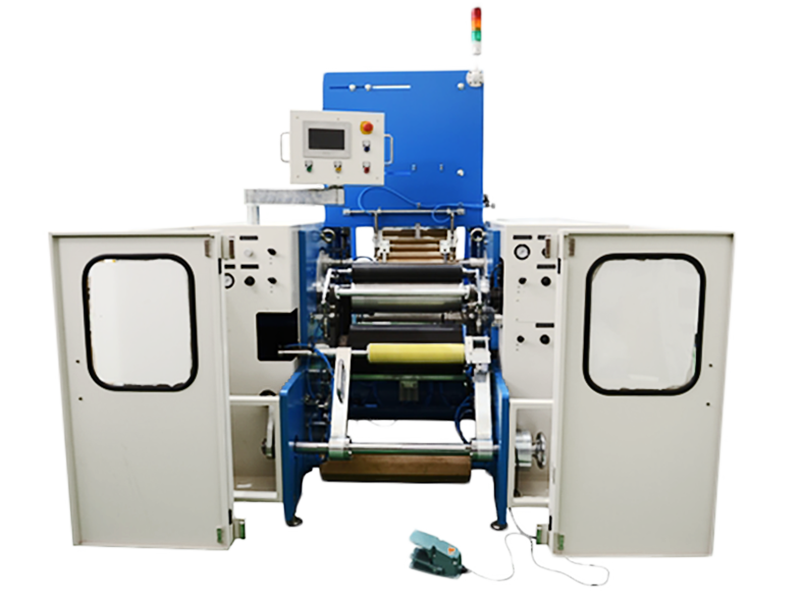

Automatic Shrink Film Packaging Machine

TPG 50

The PG50 Automatic Shrink Film Packaging Machine is designed for roll-type products and integrates seamlessly with rewinder machines for fully automated packaging. It features a 3-stage conveyor system, supports BOPP, PVC, and PE films, and offers customizable wrap lengths or MARK point alignment.

Product Feature

The PG50 Automatic Shrink Film Packaging Machine is purpose-built for roll-type products and can be connected in-line with a rewinder machine to enhance packaging precision and overall production efficiency.

- In-line automatic packaging: Installs behind the rewinder for continuous, fully automated packaging—reducing manual labor.

- Three-stage conveyor system: Equipped with three conveyors for feeding, film processing, and discharging, ensuring a clear and stable workflow.

- Smart feeding options: Choose between timed feeding or sensor-based automatic feeding for greater flexibility and accuracy.

- Wide material compatibility: Supports BOPP, PVC, PE, and other shrink films, with customizable wrapping lengths.

- MARK point detection: Detects printed mark points on shrink film for precise film positioning and alignment.

- Integrated labeling feature: Optional label applicator allows label paper to be inserted before shrink wrapping, creating a unified branded package.

- Refined product presentation: Built-in static eliminator and hot air shrink system ensure tight, clean, and professional-looking packaging results.

Project

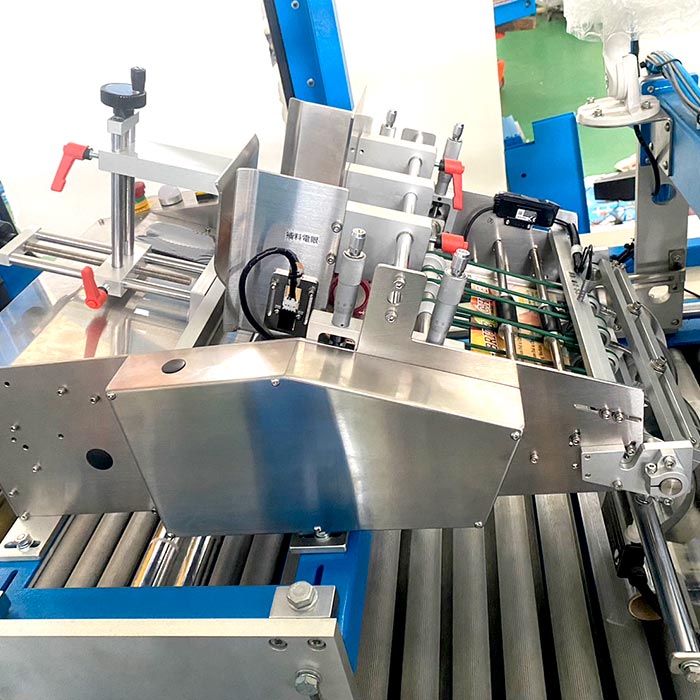

Product Details

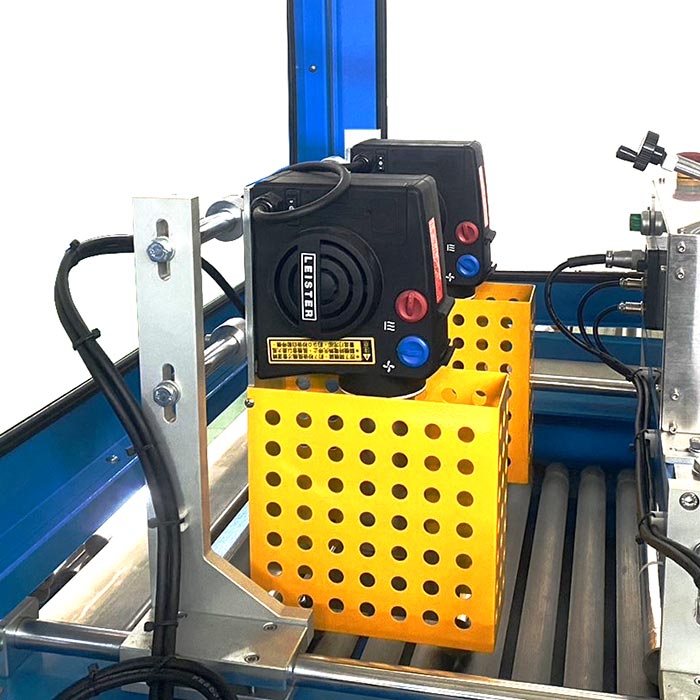

Hot-air system

labelling system

Specification

| Type of film | Shrink film |

|---|---|

| Shrink film inner core diameter | 3” (76mm) |

| Shrink film width | 305 - 505 mm |

| Shrink film thickness | 20 micron |

| Shrink film outer diameter | 300 mm |

| Outer wrapping film length | 170 - 185 mm |

| Semi-finished product outer diameter | 30 - 45 mm |

| Semi-finished product width | 300 - 470 mm (Max.) |

| Mechanical productivity | 20 rolls/min. (Max.) |

| Installed power | 7 KW |

| Power supply | 220V, 50Hz, 3ph |

| Dimensions L x W x H | 2800 x 1950 x 1800 mm |

| Net weight | 2500 kg |

Related Products.

Contact Us Now