Applications of Rewinder Machines in the Cosmetics Packaging Industry

In the cosmetics industry, where aesthetics and product preservation are key, packaging materials play a crucial role—not only in enhancing visual appeal and brand image, but also in ensuring content stability and quality. Thanks to its excellent moisture resistance, anti-oxidation, and light-blocking properties, aluminum foil has become a vital material for packaging skincare and beauty products. To meet on-site processing and dispensing needs, the aluminum foil rewinder machine serves as an essential part of the packaging workflow.Advantages of Aluminum Foil in Cosmetics Packaging

Aluminum foil is commonly used in:- Facial mask pouches and aluminum foil lid films for essence packaging

- Sealing films for skincare creams and lip balms

- Perfume sample cards and promotional backing sheets

Facial Mask Packaging: Preserving Freshness and Enhancing Brand Value

Modern facial mask products focus on ingredient potency and airtight sealing. As a result, aluminum foil pouches are a preferred choice for premium brands. These materials provide excellent protection against light, moisture, and oxidation, greatly extending shelf life and product stability. Using fully automatic aluminum foil rewinder machines and semi automatic aluminum foil rewinder machines, bulk foil rolls can be slit and rewound into roll formats compatible with automated packaging equipment. Integrated with multi-step sealing operations, this solution significantly boosts packaging efficiency and reduces manual handling. It is especially suitable for OEM/ODM facial mask manufacturers and beauty contract packaging lines.Aluminum Lid Film Processing: Enhanced Sealing for Skincare Products

Aluminum lid films are widely used for sealing jars and bottles containing creams, gels, serums, and foundations. They provide a critical barrier that prevents leakage, oxidation, contamination, and fragrance loss. During production, cosmetic factories use lid films matched to container specifications and apply them in bulk for sealing operations. These lid films are typically converted from jumbo aluminum foil rolls and must be processed in advance using aluminum foil rewinder machines to ensure flatness, consistent tension, and wrinkle-free performance. The fully automatic aluminum foil rewinder supports high-speed sealing lines, improving sealing yield and bonding success—making it an indispensable tool in modern automated beauty product production.Aluminum Foil Roll Conversion: Key to Packaging Efficiency

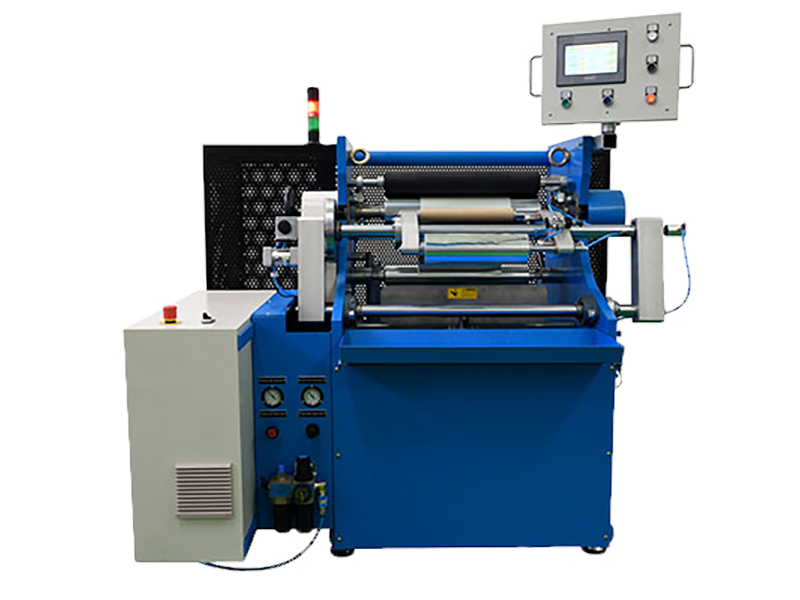

To integrate with sealing equipment, packaging lines, and manual workflows, cosmetics manufacturers often need to cut large aluminum foil rolls into specific roll sizes. This task can be accomplished using either a fully automatic aluminum foil rewinder machine or a semi automatic aluminum foil rewinder machine, depending on production scale and flexibility needs:- ✅ Fully Automatic Aluminum Foil Rewinder Machine: Ideal for large-scale continuous production, capable of automatic feeding, rewinding, cutting, and roll collection—minimizing labor and maximizing consistency.

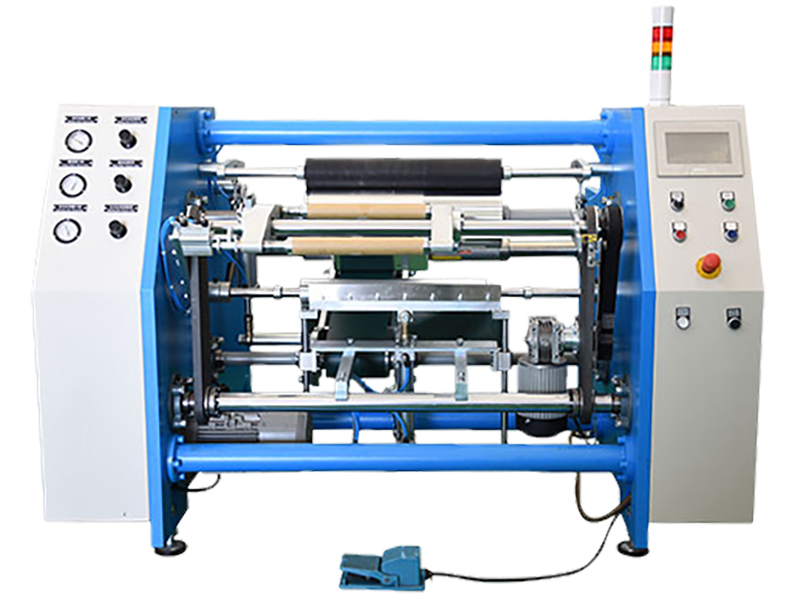

- ✅ Semi Automatic Aluminum Foil Rewinder Machine: Suitable for small to medium production, with simpler structure and flexible adjustment—perfect for multi-product lines or low-volume orders.