Diversified Applications of Rewinder Machines in Food Packaging

The primary goals of food packaging are to extend shelf life, ensure hygiene, and enhance product value. Packaging materials such as aluminum foil, cling film, and parchment paper play a vital role in households, the food service industry, bakeries, and ready-to-eat food production. With the use of rewinder machines, bulk materials can be efficiently processed into portable, easy-to-use roll formats—improving operational efficiency and minimizing material waste. These machines have become indispensable equipment on modern food packaging lines.Home & Foodservice Use: Everyday Applications of Cling Film

In home kitchens, cling film is widely used to wrap leftovers, prevent moisture loss, and block odors—helping maintain food freshness. Restaurants, bento shops, and food delivery services also rely heavily on cling film for takeaway and ready-to-eat meal packaging to ensure hygiene and convenience. By utilizing fully automatic cling film rewinder machines or semi automatic cling film rewinder machines, food-related businesses can process raw film materials into various roll sizes and lengths tailored to on-site needs.Bakery & Ready-to-Eat Lines: High-Demand Use of Baking Paper

Baking paper (such as greaseproof paper or silicone-coated parchment paper) is widely adopted in the baking industry for its heat resistance, non-stick surface, and protective packaging function. It helps preserve the appearance and texture of cookies, cakes, and other ready-to-eat products. A baking paper rewinder machine enables quick conversion of jumbo rolls into manageable rolls for daily use in pastry factories, bakeries, and chain baking brands.Aluminum Foil Packaging: A Kitchen & Culinary Essential

With light-blocking, anti-oxidation, moisture-resistant, and heat-resistant properties, aluminum foil is highly valued across food processing, home cooking, and commercial catering. It is commonly used for cooked food wrapping, tray lining, and container sealing. Fully automatic aluminum foil rewinder machines and semi automatic aluminum foil rewinder machines convert bulk rolls into application-ready formats of various sizes, facilitating both storage and on-site operations.Boosting Efficiency: Integrated Application of Automatic Shrink Film Packaging Machines

After rewinding, a TPG 50 Automatic Shrink Film Packaging Machine can further upgrade packaging with dust-proof, waterproof, and tamper-evident seals—ideal for cake boxes, frozen meals, and ready-to-eat bento products. It enhances packaging quality and reinforces brand professionalism.Conclusion: Building a High-Efficiency Food Packaging Solution

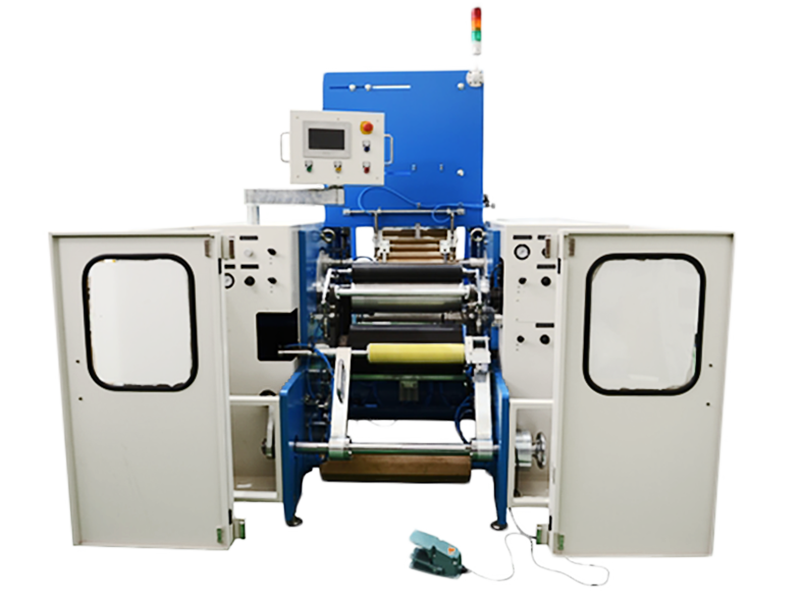

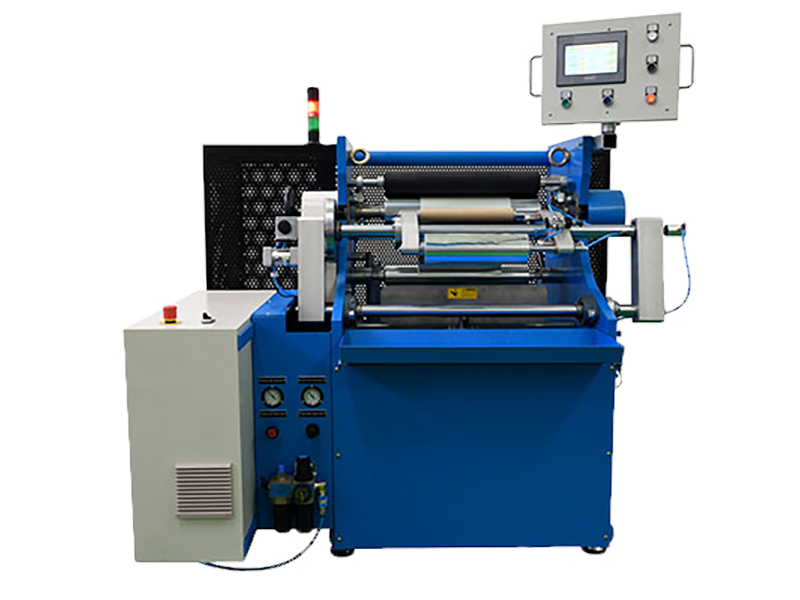

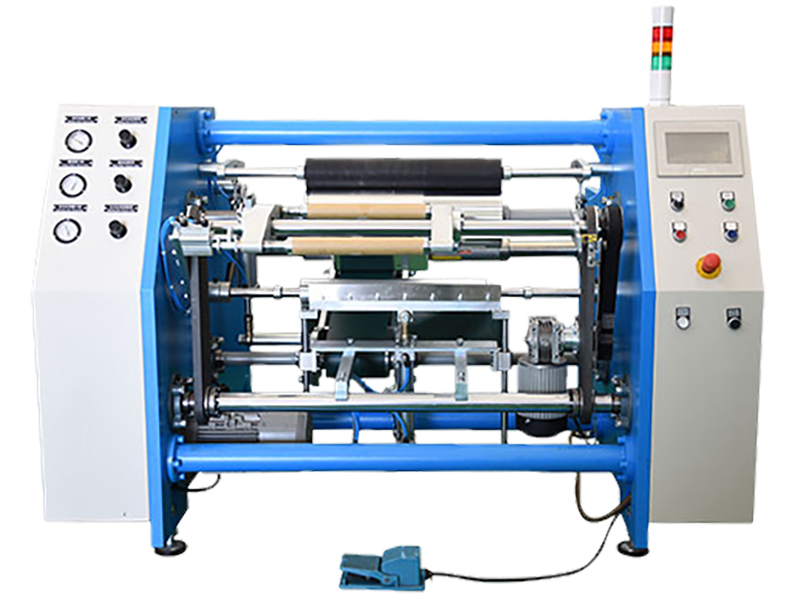

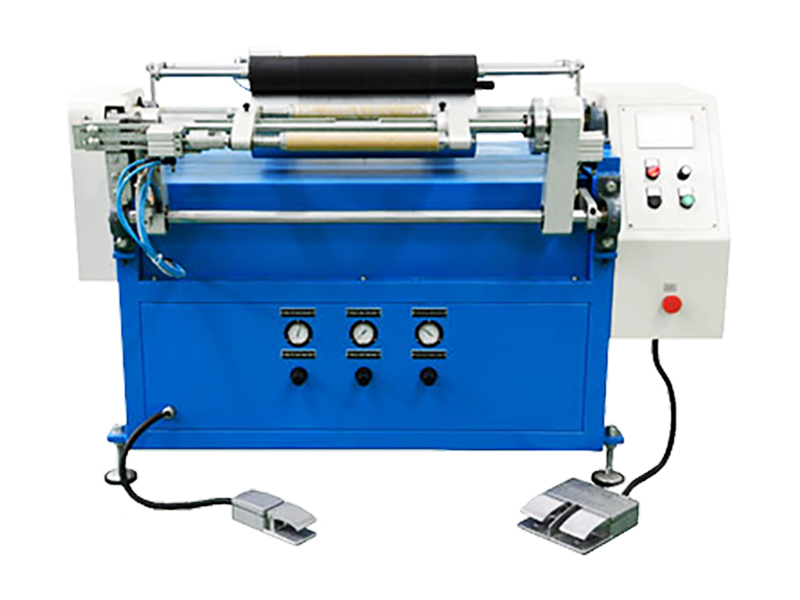

From home kitchens and central kitchens to bakeries and large-scale food processing plants, rewinding and packaging processes are key to improving both efficiency and quality. Choosing the right rewinding equipment such as:- AH-6S Six Shafts Type Automatic Aluminum Foil / Cling Film Rewinder

- AH-FW Four-Shafts Type Automatic Cling Film Rewinder (Adjustment)

- TB-CW-3S or TB-ACS-3S Three-Shafts Type Automatic Cling Film Rewinder

- SR-2S or SRB-A-2S Semi Automatic Aluminum Foil Rewinder

- Baking Paper Rewinder Machine

- TPG 50 Automatic Shrink Film Packaging Machine