Smart Manufacturing Upgrade for Vietnam's Leading Packaging Supplier – TINH UY CO., LTD

Client Background

TINH UY CO., LTD is a well-known plastic food packaging manufacturer in Vietnam with extensive experience in production and export. The company specializes in PE/PVC cling film, aluminum foil, parchment paper, and other consumable packaging materials. With a customer base spanning Southeast Asia and the Middle East, TINH UY places high emphasis on production capacity, product quality, and packaging efficiency.

Challenges & Needs

As their market scale expanded, TINH UY faced an increase in order volume that their existing equipment struggled to meet. Additionally, the complexity of handling various paper core sizes and rewinding materials required greater flexibility. The company needed to reduce manual labor dependency and enhance automation and operational stability to remain competitive.

Solution

To help TINH UY meet these growing demands, we provided a comprehensive set of rewinding equipment tailored to support both automation and production line flexibility:

● AH-FW-4S Four-Shafts Type Automatic Cling Film Rewinder (Adjustment)

- Specially designed for rewinding PE/PVC cling film

- Each shaft equipped with independent chuck for core holding and releasing

- Fully automated material loading/unloading

- Features a brushing device to curl the tail end for easy user access

● TB-CW-3S Three-Shafts Type Automatic Cling Film Rewinder (Adjustment)

- Handles larger paper cores and extended rewind lengths

- Rewinds up to 1000 meters per roll with core diameters up to 76mm

- Ideal for large-scale and export-focused production

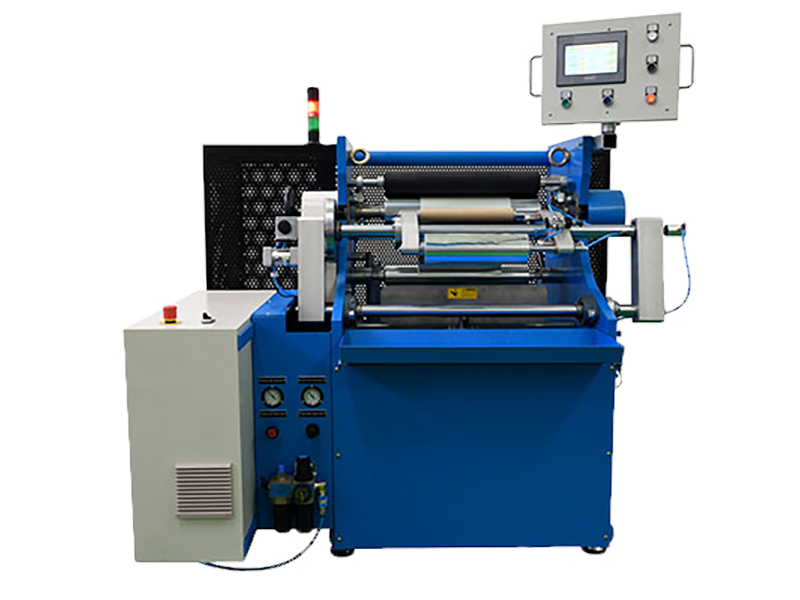

● AH-6S Six Shafts Type Automatic Aluminum Foil / Cling Film Rewinder

- Compatible with aluminum foil, parchment paper, and PE/PVC cling film

- Equipped with precision pressure gauge and valve on press rollers

- Offers optional label sticker or hot melt glue device for perfect product closure

- Core diameter range: 25–38mm; max roll outer diameter: 80mm

● SR-2S Two-Shaft Type Semi-Automatic Aluminum Foil & Cling Film Rewinder

- Supports rewinding aluminum foil, parchment paper, and PE/PVC cling film

- Features auto-cutting and fixed feeding for easy operation

- Core diameter range: 25–76mm; max roll outer diameter: 150mm

● SRS-1S Single-Shaft Type Semi Automatic Cling Film Rewinder

- Tailored for PE/PVC cling film

- User-friendly touchscreen interface

- Includes shaft back-off timer setting for safer operation

- Core diameter range: 25–45mm; max roll outer diameter: 150mm

Implementation Results & Benefits

After adopting a combination of fully automatic and semi-automatic rewinding equipment from TRU-BRITE MACHINERY, TINH UY CO., LTD experienced a significant boost in production efficiency. Fully automated machines replaced labor-intensive manual processes, streamlining the rewinding of cling film and aluminum foil, and increasing production output by nearly 70%. This upgrade enabled them to meet delivery deadlines more consistently.

The flexibility provided by multi-model deployment allowed TINH UY to switch between different product formats quickly, catering to various order specifications with ease. The intuitive interface and stable tension control systems on each machine reduced the learning curve for new operators and ensured consistent product quality. Tail-end curling and clean cuts gave their finished rolls a professional appearance, enhancing their competitiveness in the global export market.

Conclusion

With the successful integration of various rewinding solutions, TINH UY CO., LTD completed a seamless transition to an upgraded, automated production line. This advancement has laid a strong foundation for their continued growth and expansion into the international market.